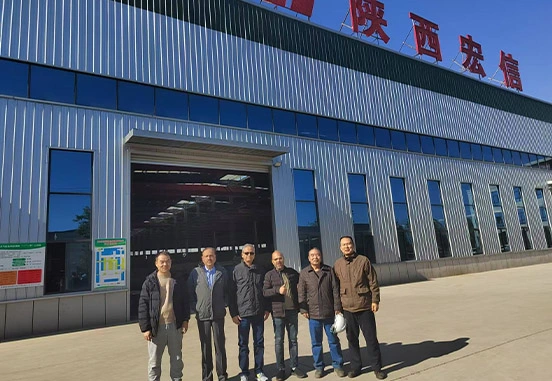

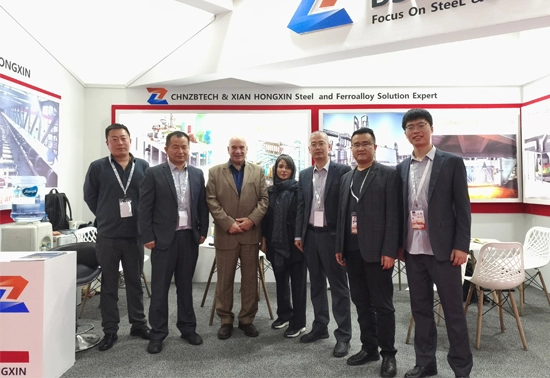

Astana, Kazakhstan — Tau-Ken Temir LLP, one of the leading companies in the domestic industrial silicon sector with an annual production capacity of 30,000 tons of metallurgical silicon, recently wel...

back homepage

back homepage

- LRF Ladle Refining Furnace

- ESR Electroslag Remelting Furnace

- VOD Vacuum Oxygen Decarburization

- AOD Argon Oxygen Decarburization

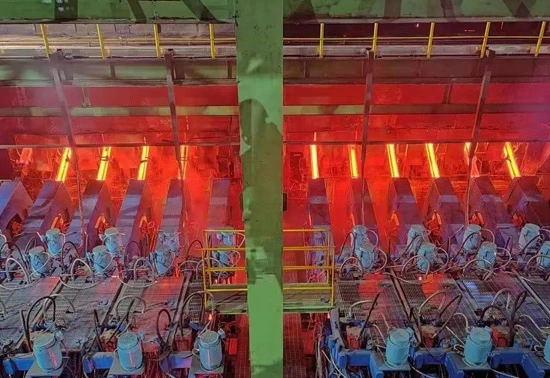

- Silicon Metal Furnace

- Ferrosilicon Furnace

- Silicomanganese Furnace

- Corundom Furnace

- DC Submerged Arc Furnace

- Low Carbon Ferrochrome Furnace

EN

EN

fr

fr  ar

ar  fa

fa