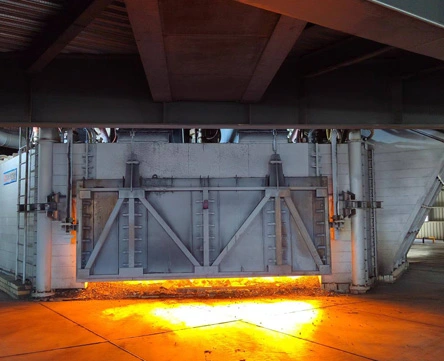

CHNZBTECH’s Submerged Arc Furnace (SAF) technology is making significant strides in revolutionizing ferroalloy production. Ferroalloys are essential in the steelmaking process, as they are used to introduce specific properties to steel, such as increased strength, corrosion resistance, and improved ductility. The SAF technology from CHNZBTECH offers numerous advantages that enhance the efficiency, quality, and sustainability of ferroalloy production. CHNZBTECH’s Submerged Arc Furnace (SAF) technology is revolutionizing ferroalloy production by offering advanced technology, improved production efficiency, energy efficiency, high quality and consistency, environmental sustainability, safety and reliability, customization and flexibility, strong support and service, and a commitment to innovation and continuous improvement. These advantages make CHNZBTECH SAFs a compelling choice for ferroalloy producers looking to enhance their production capabilities, reduce costs, and meet the growing demand for high-quality ferroalloys in the steel industry.

Diversity in SAF Submerged Arc Furnaces

CHNZBTECH’s Submerged Arc Furnaces (SAFs) are versatile, including silicon metal furnace and ferrosilicon furnace, and can be adapted for a wide range of applications in the metallurgical industry. The diversity in SAFs allows them to be used for producing various types of ferroalloys and other metallurgical products. The diversity in the SAF Submerged Arc Furnace allows them to cater to a wide range of applications in the metallurgical industry. From producing various types of ferroalloys to accommodating different furnace designs, capacities, energy sources, raw materials, and process variations, SAFs offer unparalleled flexibility and efficiency. This versatility makes SAFs an essential tool for modern ferroalloy production, enabling steel furnace manufacturers to meet diverse production needs while maintaining high standards of quality, efficiency, and environmental sustainability.

Key Features of CHNZBTECH SAF

CHNZBTECH’s Submerged Arc Furnace (SAF) technology offers a range of advanced features that enhance the efficiency, quality, and sustainability of ferroalloy production. Key features include high-efficiency electrode systems, robust construction, energy efficiency, advanced control systems, environmental sustainability, comprehensive safety features, customization and flexibility, high production efficiency, integration with Industry 4.0, and compliance with global standards. These features make these types of steel making furnaces a compelling choice for ferroalloy producers looking to optimize their operations and meet the growing demand for high-quality ferroalloys in the steel industry.

CHNZBTECH SAF's Impact on Ferroalloy Production

CHNZBTECH’s Submerged Arc Furnace (SAF) technology has a significant impact on ferroalloy production by enhancing production efficiency, improving product quality, increasing energy efficiency, promoting environmental sustainability, ensuring safety and reliability, offering customization and flexibility, driving innovation, boosting global competitiveness, reducing operational costs, and providing strong support and service. These benefits make CHNZBTECH SAFs an indispensable tool for ferroalloy producers looking to optimize their operations, reduce costs, and meet the growing demand for high-quality ferroalloys in the steel industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa