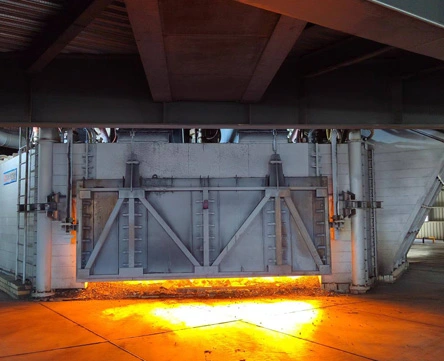

When it comes to the steelmaking process, the Vacuum Oxygen Decarburization (VOD) furnace holds a paramount position. This versatile tool plays a vital role in refining high alloy steel and is an integral part of any industry. Like any other sophisticated piece of equipment, maintaining a VOD furnace and understanding how to troubleshoot common issues is crucial for its optimal performance. In this blog, we steel furnace manufacturers will walk through four main aspects to give you a clear understanding of the maintenance procedures and common issues you might encounter with a VOD furnace.

Understanding the VOD Furnace

Before starting on the maintenance and troubleshooting procedures, understanding the workings of a VOD refining furnace is essential. VOD furnaces specifically use vacuum and oxygen to reduce the carbon content of steel (decarbonization). This process also results in the removal of unwanted elements like sulfur and phosphorus, ensuring the production of high-quality steel with enhanced ductility. Proper knowledge about these functionalities would make the maintenance and troubleshooting procedures more effective.

Regular Maintenance of VOD Furnace

Regular maintenance of a VOD furnace will prolong its lifespan and prevent any unexpected malfunctions. An established routine includes regular checking of connections, routine cleaning, regular inspection of vacuum seals, lubrication of moving parts and replacing parts that show signs of wear and tear. It is also vital to keep a maintenance log to track any recurring problems, repairs made, and parts replaced. This record can serve as a helpful guide in diagnosing potential future issues with the VOD furnace.

Troubleshooting Common Issues

Knowing how to quickly address an issue during operation can save considerable time and prevent further damage. Some common issues encountered with VOD furnaces include problems with the vacuum system, irregularities in the oxygen system, mechanical faults, and electrical problems. A trouble light, visible and auditory alarm system and temperature indicators might help in identifying and addressing potential problems quickly. Always ensure to properly train your staff in such troubleshooting measures.

Essential Safety Measures

The final consideration is safety, which should never be underestimated. Due to the high temperatures and the complex nature of operations involved with a VD furnace, regular safety checks should be a top priority. All the safety protocols established by regulatory authorities should be strictly followed, and personnel should be well trained in these measures. Special care should be taken to keep the control panel at a safe and accessible location, avoiding countering anyone's path, and to keep fire extinguishers and first aid facilities readily available.

Maintaining and troubleshooting a VOD furnace need not be a daunting task. Though it does require some technical knowledge and expertise, a regularly followed preventive maintenance program can ensure that your VOD furnace continues to function optimally and that you experience minimal downtime in your operations. Be it maintenance handling, troubleshooting, or safety, the key lies in being proactive and prepared. Your VOD furnace is a crucial asset, and managing its maintenance and troubleshooting efficiently is instrumental for a successful business operation.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa