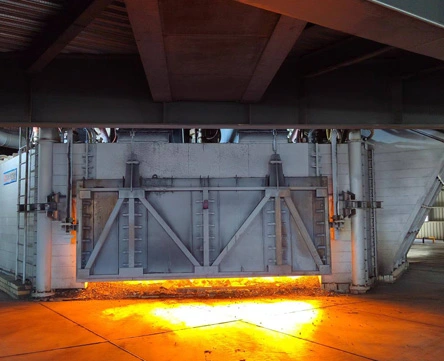

Recently, CHNZBTECH achieved a major milestone in the EPC project for Oman’s 2×33,000 KVA industrial silicon SAF, with the first batch of core equipment officially dispatched. This shipment includes key components such as the furnace shell, fume hood, and rotating mechanism, marking the commencement of the delivery and installation phase for Oman’s largest industrial silicon SAF.

As the largest SAF for industrial silicon in Oman, the 2×33,000 KVA smelting system adopts internationally advanced design, featuring high efficiency, energy savings, and low-carbon environmental benefits. Once operational, it will significantly boost local silicon production capacity, providing strong support for high-end photovoltaic and semiconductor materials, including monocrystalline and polycrystalline silicon.

Phased Shipment & Professional Support

The complete equipment will be delivered in four batches to ensure transportation safety and on-site installation efficiency. A CHNZBTECH project manager stated that a dedicated technical team has been assembled, and senior engineers will be dispatched to Oman for full-process installation guidance and commissioning upon the arrival of all equipment, ensuring the smooth operation of this flagship project.

Strengthening Cooperation & Expanding in the Middle East

The Omani client highly commended the project’s progress, acknowledging CHNZBTECH’s technical expertise and delivery capabilities as key drivers for local industrial advancement. This collaboration not only fills the gap in large-scale industrial silicon smelting equipment in Oman but also sets a benchmark for Chinese intelligent manufacturing in the Middle East’s renewable energy sector.

CHNZBTECH emphasized its commitment to global green energy industry needs, promoting the synergy between high-end equipment manufacturing and renewable energy development through technological innovation and international cooperation.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa