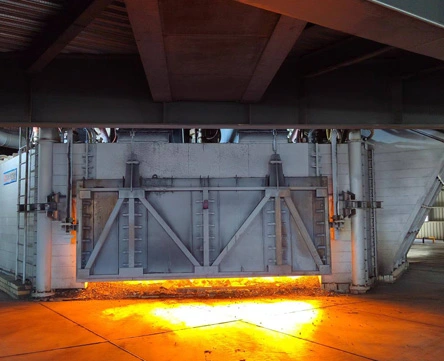

The AOD (Argon Oxygen Decarburization) is a refining process used primarily in steelmaking, particularly in the EAF (Electric Arc Furnace) smelting process. It involves injecting a mixture of oxygen and argon into molten steel to lower the carbon content.

Function in EAF smelting:

Decarburization: The AOD process helps in reducing the carbon content in the molten steel, making it suitable for producing high-quality stainless steels and other alloys.

Temperature Control: The argon injection ensures better control of the process temperature by assisting in the removal of carbon and other impurities.

Alloying: It allows for the addition of alloying elements like chromium, nickel, and manganese to achieve the desired steel composition.

Overall, as one of the key business scopes of CHNZBTECH, AOD (Argon Oxygen Decarburization) is crucial for refining steel within the EAF, ensuring the correct chemical composition for specific steel grades.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa